|

|

||||||||||||||||||||||||||||||

|

|

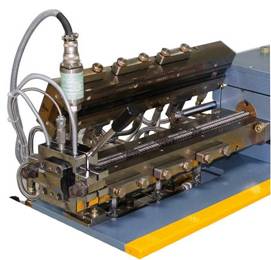

μCompounder Modular 12 mm twin-screw extruders types LTE 12-36 with segmented screws and screw speeds up to 800 RPM |

|||||||||||||||||||||||||||||

|

Available both in manual as well as fully computerized version with LCD touch screen controls

The New MicroCompounder 12 mm co-rotating twin screw extruders is made with a complete modular build up of the clam shell barrel, where each barrel section have a length of 9D or 108 mm. The length is available with 36 L/D and with drive power of 2.2 KW.

This twin is designed to be used with polymers in powder or micro pellets form with an approximate maximum granule diameter of 1.5 mm. It is suitable for processing of minute polymer quantities for research applications but it can also produce larger quantities having a maximum output of around 4 kg/hr. The amount of resin remaining in the screws is only around 10 grams so if the batch size is for instance 50 gram, the amount of polymer which is compounded and exits through the die is 40 gram.

The Clam Shell Barrel is equipped with exchangeable barrel lining inserts for optimum economy and ease of replacement. These standard inserts are made from a very high grade tool steel which is through hardened to over 60 RC and which can withstand high processing temperatures of up to 400 °C. This unique barrel insert system was designed by us in 2003 and has proven during the years to be a very good feature. The screws are built up from individual single elements mounted on hexagonal hardened shafts. Each individual kneading elements is supplied in many angles to enable optimum variations in screw configurations. The screw components are made from high grade tool steel which is through hardened but made with a slightly softer hardness than the barrel to ensure optimum life time for both elements and barrel.

Each barrel zone is equipped with both water cooling and electric cartridge heating. This allows for complete process control at each zone of the barrel and the water cooling coupled with the high wattage heating enables fast temperature changes of each zone when changing processing conditions from one compound to another. The water cooling is done from fine channels inside each barrel module and regulated with individual solenoid valves from its designated temperature controller. The in feed section of the barrel is equipped only with water cooling and no heating. The extruders are, as standard, equipped with a one hole (3 mm) strand die with a very short distance from strand hole entry to screw tips for easy cleaning. The die is of swing open type fastened with two bolts to the barrel and it is equipped with a breaker plate. A 0 to 100 bar melt pressure transducer with melt temperature sensing is mounted at the die end and connected to a pressure controller on the control panel. The extruders are supplied complete with a stainless steel volumetric hopper feeder with a “spiral type” screw and with a stirring arm (agitator) above the feeding screw. The hopper feeder can optionally also be equipped with twin screws. The 36 L/D extruder is, as standard, supplied with an atmospheric venting zone on one of the barrel modules which can be converted to vacuum. The standard atmospheric vent opening can optionally be equipped with a vacuum housing made from stainless steel with sight glass and vacuum manometer which in turn is connected to a vacuum pump and a large stainless steel filter to protect the pump. Summary of standard features: ¨ 12 mm co-rotating segmented screws where each segment can be placed anywhere on the hexagonal screw core shaft for optimum flexibility of screw configurations. The kneading elements are supplied as single sectors which can be placed against each other in various angles enabling numerous kneading and shearing functions. ¨ The clam shell barrel is with 36 L/D and each module has a length of 9D. Barrel with balanced hinged top part for easy opening and access to the screws. ¨ Screws can also easily be pulled out at the front without opening of the clam shell barrel. ¨ The modular Clam Shell Barrel is equipped with exchangeable barrel lining inserts made from a special high grade tool steel which have been through hardened to over 60 Rockwell C. This special steel also allows for high temperature extrusions of up to 400 °C ¨ The screw and kneading elements are made from high grade tool steel with through hardening and with a surface hardness of slightly below the hardness of the barrel. Also the hexagonal screw shafts are made of treated tool steel for optimum stiffness and high torque applications. ¨ Variable screw speeds with RPM from 0 to 800 controlled via an AC frequency inverter. ¨ Electric cartridge heating of each barrel module. ¨ Water cooling as well as electric heating of each barrel module. ¨ Atmospheric venting zone. Optionally the vent can be equipped with vent housing and vacuum pump system with vacuum gauge and bypass valve.. ¨ Variable speed single screw (spiral type) hopper feeder with stirring arm over the screws. Feeder components are equipped with quick locks for easy cleaning and the whole feeder assembly can easily be slid backwards for access to the extruder in-feed opening. ¨ Practical one-hole strand die mounted on hinged a support connected to barrel with two bolts. Also equipped with easy removable breaker plate in extruder flange, enabling production with or without a screen pack. ¨ 100 bar pressure transducer at screw end, also equipped with melt temperature sensor. Additionally melt sensors are placed on every second module, connected to digital temperature indicators on the control panel. ¨ Screws protected by a torque limiter mounted in between motor and gear box. ¨ Modern design with a sturdy sub cabinet containing all electric and electronic components in compartments completely separated from the vacuum pump assembly. ¨ Control panel mounted on the body of the extruder and containing the following: · Programmable pressure controller with digital indication of the screw tip pressure. · Digital RPM indicators for main screws speed as well as feeder screws speed with UP/DOWN scroll buttons to regulate speeds.

Click Here to see screw elements available:

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Call (810) 516-1700 for Pricing |

||||||||||||||||||||||||||||||

| Covering Michigan, Ohio, Ind, Ill, Canada for LabTech Engineering Co. | ||||||||||||||||||||||||||||||

|

Milabtech LLC 2009 14042 Iroquois Woods Dr. Fenton, Michigan 48430 |

||||||||||||||||||||||||||||||