NEW

Scientific

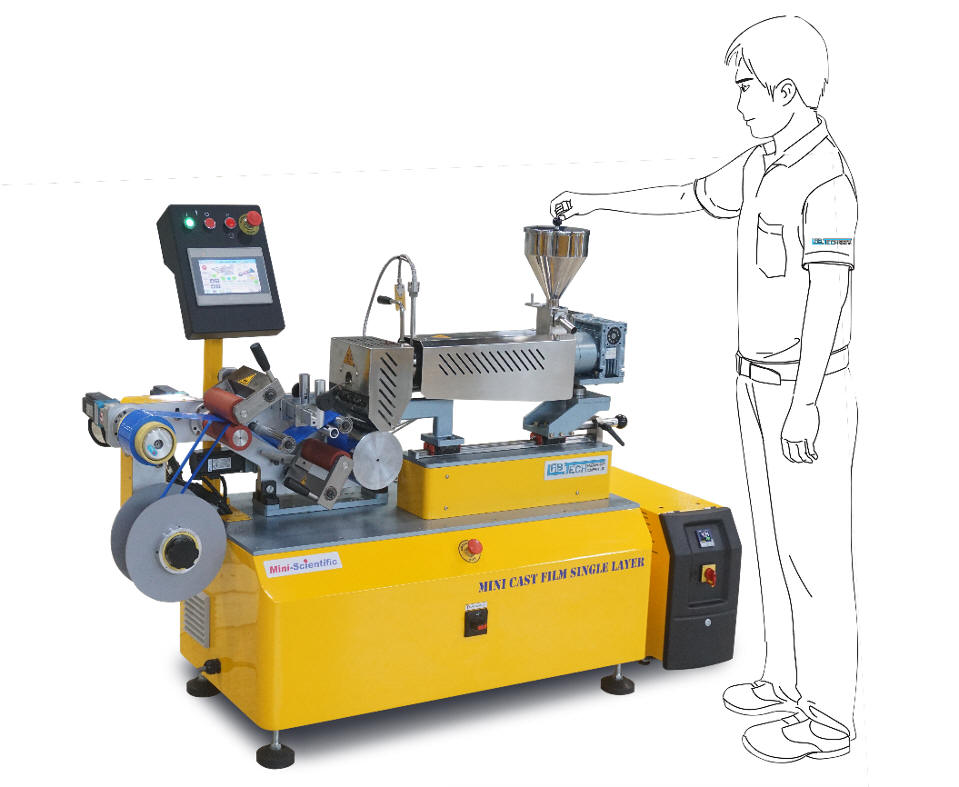

Mini

WITH 16 MM, 30 L/D EXTRUDER FOR PROCESSING MANY RESIN TYPES AND ALLOWING

OPTIMUM DISPERSION OF ADDITIVE MASTERBATCHES

Our

New Scientific Mini

Single-Layer Film and Sheet Line Type

LMCR-150

is

a viable low-cost alternative to our regular cast film lines.

It

has a mini-size extruder connected to a single-layer cast film

die,

and it is

equipped with a vertically adjustable chill roll with a diameter of 145

mm and a width of 150 mm. This single-layer mini cast film can process

PE, PP,

PA6, PC, PET, EVOH, PLA,

PS, ABS,

and many other resin types.

Ø

Mini

design taking up a

floor space of only 1.5 m x 0.7 m (5.0 x 2.3 ft) and a height of 1.2 m

(4.0 ft) make it easy to fit into even the most crowded lab.

Ø

The Mini Extruder can process regular polymer pellets

Ø

The entire assembly is mounted on a sturdy steel subcabinet containing

all major supply cables and electric components inside the subcabinet,

giving a very clean appearance with very few visible connections to the

extruder.

Ø

The mini single-screw extruder is mounted

on an elevated base on top of the subcabinet

Ø

The die and the extruder are

mounted individually on the same

guiding rod,

and the die can be separated from the extruder with a quick lock

C-clamp. This enables easy

Ø

Ø

Ø

The film tensioning nip is opened with a handle, and the nip force is

adjustable with a spring-loaded screw

Ø

Ø

The chill roll, haul-off nip-roll, and wind-up device are driven by

three individual AC servo motors

Ø

·

extruder temperature and RPM

·

die temperature

·

chill roll temperature and RPM

·

downstream nip-roll and wind-up RPM

MINI CHILL ROLL SHEET/FILM ATTACHMENT

TYPE LMCR-150 FEATURES

¨

¨

The roll is vertically adjustable so that the gap between the die and

the roll can be adjusted to reduce the neck-in of the extruded melt from

the die

¨

The roll

is made from high-grade tool steel, which has been precision ground,

hard chromed with surface roughness (Ra) of 0.01-0.03 µm, and then

polished to a mirror surface

¨

The roll

is equipped with rotary joints and cored inside for cooling/heating

water, enabling efficient temperature control of the roll surface. A

valve is fitted to the inlet of the roll so that the flow of the water

can be individually regulated

¨

The roll

is driven with a variable speed AC servo motor

¨

The

rubber haul-off nip-rolls give the film and sheet a steady and even

pull-off from the chill roll stack.

The pressure of the nip-roll is adjustable with a spring.

¨

The

rubber pressing roll can manually be positioned either off or against

the chill roll and is adjusted with a spring-loaded screw

¨

The

haul-off nip-rolls are driven with a geared AC servo motor unit

¨

The

wind-up unit can hold a max film width of 125 mm with a max diameter of

250 mm. The unit is equipped with an air shaft to hold 3-inch core

bobbins, and the shaft is driven with a geared AC servo motor

¨

Line

speed is from 0 to 10 meters/min

¨

¨

The

sub-cabinet contains all the electrical and electronic components, all

mounted on a platform with sliding rails for easy and convenient access

to all parts.

FLAT COAT HANGER TYPE DIE 125 MM FOR MINI CAST FILM

The Mini Cast Film line is supplied with a vertically downward-pointing

coat hanger type die. It is designed to process many different polymers,

producing thin films and sheets with a thickness of around 1.5 mm. And

it is equipped with many push-pull adjustment bolts for the lip, having

a lip opening from 0.3 to 2.0 mm. The die is connected to the extruder

with a C-Clamp, and it is equipped with cartridge heaters that divide

the die into left and right heating zones. Both are individually

regulated with their designated temperature controllers from the onboard

PLC connected to the touch screen panel. The standard die for mini cast

film is made with a max temperature of 300°C.

|

Technical Data for Mini Chill Roll Attachment Type LMCR-150 |

||||

|

Roll Width |

|

mm |

150 |

|

|

Roll Diameter |

|

mm |

145 |

|

|

Maximum Film Width (untrimmed) |

|

mm |

115 |

|

|

Maximum Die Width |

|

mm |

125 |

|

|

Die lip gap range |

|

mm |

From 0.1 to 2 |

|

|

Film minimum thickness, depending on resin type |

|

µ |

10 |

|

|

Sheet max thickness, depending on resin type |

|

mm |

1

|

|

|

AC Servo Motor Drive Power for Chill Roll |

|

kW |

0.4 |

|

|

AC Servo Motor Drive Power for Nip Rolls |

|

kW |

0.4 |

|

|

Take-Off Speed |

|

m/min |

0

– 10 |

|

|

Maximum Winding Diameter of Film Roll |

|

mm |

250 |

|

30 L/D

Mini

Single-Screw

Extruder

with 16 mm Diameter

Type LME16-30/C

Mini

Non-Vented

Extruder for processing of most types of Cast Film Resins

General Design

·

New

Mini version with a diameter of 16 mm and L/D ratio of 30

·

The

extruder is mounted on a heavy-duty platform equipped with sliding

rails.

·

The

extruder can easily be separated from the die and turned to the front

for the purging of the barrel and removing of the screw

·

C-clamp

on the barrel flange allows for quick and secure connection of the die

Barrel and Screw

·

Barrel and screw are made of high‐grade steel, which has been nitrided

and polished. Optionally

barrel and screw can be supplied with bi-metallic steel

·

·

Full stainless steel cover over the barrel with air venting grilles on

the sides

Hopper

·

Polished

stainless steel hopper with the lid mounted on a slide valve assembly

which closes the infeed to the extruder and a second slide valve at the

side for discharging the resin from the hopper

Barrel Heating and Cooling

System

·

The

barrel is equipped with two heating zones, which are accurately

regulated from the LCD touch screen control panel

·

Each zone

with high wattage heaters and efficient air cooling fan, ensuring both

fast heating to required processing temperatures as well as fast cooling

·

The

standard maximum heating temperature of 300°C

·

Water-cooled

feed section to prevent premature melting of resins

Infinitely Variable-Speed

Servo Motor on Extruder

·

The 0.75

kW AC servo motor drive is coupled directly to a worm gear, connected to

a heavy-duty thrust bearing driving the screw.

Touch Screen Control

Interface

·

The

entire line with the extruder, die layer, and downstream equipment is

controlled on a 7-inch touch screen with the

temperature and RPM control functions

|

Technical Data for Mini Single-Screw Extruder Type LME16-30 |

|

|

Screw Diameter |

16 mm |

|

Standard Screw L/D

Ratio

(other

sizes available upon customer’s request) |

30:

1 |

|

Servo Drive Motor Power |

0.75

kW |

|

Screw Speed Range |

0

-

150 rpm |

|

Number of Barrel Heating Zones |

2 |

|

Max Processing Temperature |

300°C |

|

Forced Air Cooling System on Heating Zones |

YES |

|

Maximum Output

(based

on high-pressure

LDPE cast film process) |

1,600 g/hr |

|

Can process almost all resin types Like PE, PP, PC, PLA, EVOH,

PA, PET PS, ABS etc. |

|

Price for Chill Roll Attachment LMCR-150 with Flat Die 125 mm and Mini

Single-Screw Extruder Type LME16-30,

complete

as described above excluding the Water Tempering Unit:

Call

EDGE-CUTTER AND EDGE-TRIM WIND-UP

CASSETTE

The

wind-up spindle cassette for the edge trimmings has an adjustable

knurled knob to collapse the core of the wind-up shaft for easy and

quick removal of the PVC bobbin where the trimmed edges on both sides

are wounded.

The same AC gear motor of the haul-off nip-roll drives the edge-trim

wind-up cassette.

Optional Edge-Cutter and Wind-up Cassettes for Edge-Trims, Additional

Price:

Call

DIE MELT TEMPERATURE AND PRESSURE READOUT

Combined

with Pressure and Melt Temperature Sensor placed at the inlet of the

die. With this, you will be able to control the melt temperature and

pressure to the die accurately. And the instrument can be set with an

alarm function to warn of overpressure.

Optional

Pressure and Melt Sensor E-type, Additional Price:

Call

NOTE: The mini cast film line can be

connected to the customer’s local cooling system. Also, the customer can

use their circulating tap water if the process does not concern the

temperature. However, if the customer wants a heating system, we can

offer the roll tempering units as an option.

ROLL TEMPERING UNITS

The rolls are equipped with rotary

joints and a cored heating and cooling media channels close to the roll

surface. This gives a very even temperature over the entire roll width.

The rolls can be tempered using water media for both heating and

cooling. With water units, the max roll temperature is around 140 °C.

Price for Water Tempering Units with CE Certification,

per unit:

Call

Price

for

Single-Layer

Extruder with Mini Cast Film and Sheet Line

|

# |

Description : |

1

layer |

|

1 |

Single-Layer Mini Cast Film Type LMCR-150 |

1 unit |

|

2 |

7-inch LCD Touch Screen Control Panel |

1 unit |

|

3 |

16 mm Compact Extruder LME16-30 with

Servo Motor Drive |

1 unit |

|

4 |

Flat Coat Hanger Type Die 125 mm |

1 unit |

|

Total Price for a Mini Cast Film Line excluding the Water

Tempering Unit |

Call |

|

|

Additional Price |

||

|

A |

Water Tempering Unit |

Call |

|

B |

Edge-Cutter and Wind-up Cassettes for Edge-Trims |

Call |

|

C |

Optional Pressure and Melt Sensor |

Call |

All Prices Quoted are Ex-Works Bangkok

We will be pleased to quote you a CIF to your destination

as soon as we know of your exact requirements.

Delivery time:

Presently 5 months,

Ex Works

Payment terms:

30%

deposit with the order

70%

by L/C

at sight or T/T

prior to shipment

Validity:

This quotation is valid for a period of 3 months from the date of

issue

Start up assistance is US$ 650/day + travel, subsistence, etc. at cost

Two Years Warranty on all our Machines

Our machines are now warranted for two years, valid from the

date of startup or two months after the shipment date,

whichever is the earliest.

The two-year

warranty covers all mechanical, electrical, hydraulic and

pneumatic parts with a few exceptions where the warranty

period is for only one year.

The exceptions cover intricate parts like inverters, PLC and

electronic instruments, which our suppliers only warrant for

one year.

We also warrant our heaters for one year even though they

are not warranted by our supplier.

We will be pleased to give you a copy of our warranty

certificates with full details for your kind consideration.