|

|||||||||||||||||||||

|

|

|||||||||||||||||||||

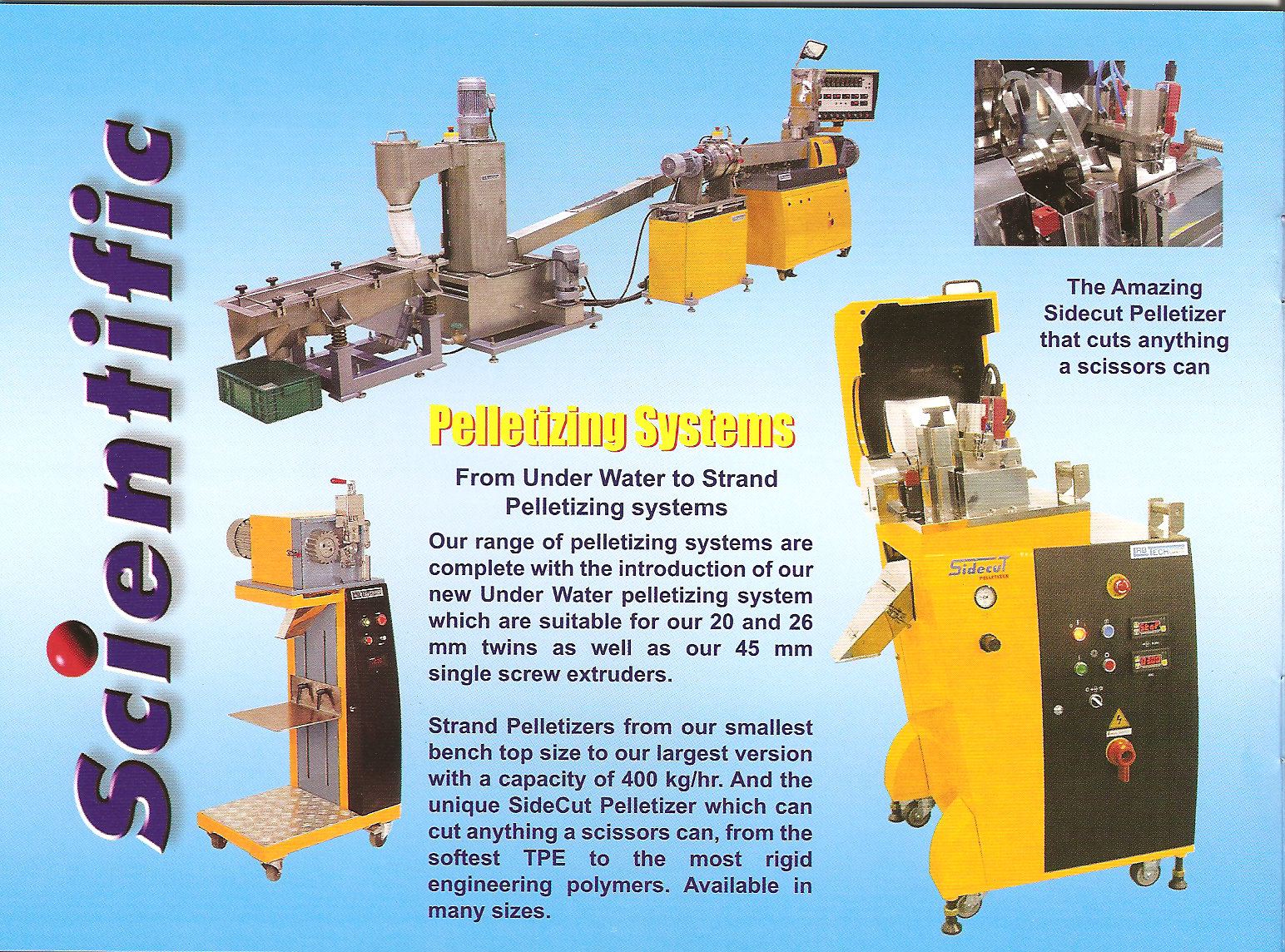

The new Sidecut Pelletizers, which are built by us with worldwide license rights from Hoshipla, Japan, represents an entirely new and unique concept of strand pelletizing of thermoplastics.

The pelletizer uses a fan-shaped cutting wheel that cuts the strands sideways with a scissors action.

The machine can be used to pelletize practically any type of thermoplastic resin, even materials that cannot be pelletized using conventional machines, i.e. ‘rubbery’ materials such as soft PVC and thermoplastic elastomers.

Because of the gentle shear cut action obtained with this Sidecut pelletizer, even highly filled and brittle strands can be pelletized without causing dust and shattering of the pellets. Anything that can be cut with scissors can be cut with this pelletizer. Even very soft thermoplastic rubbers with Shore A hardness as low as 5 have been pelletized successfully.

Conventional plastics, as well as the tough reinforced engineering types, are equally easy to pelletize.

The Sidecut Pelletizer can also produce very long pellets of up to 50 mm lengths which are very useful for fiber reinforced engineering plastics, where it is important not to cut up the pellets to short to spoil the strength of the resin. Another unique feature of the Sidecut pelletizer is that it is available in a special versions used to produce extremely small, perfectly cut micro pellets with diameters as low as 0.3 mm between the cutting knives.

Strand Pelletizer type LZ-120

Equipped as following:

"

Speed regulation with programmable inverter. Knife speed from 0 to 1200 RPM, strand feeding speed from 0 to 72 meter per minute."

Modern designed full steel body with stainless steel bottom platform as well as a smaller adjustable stainless steel platform for holding smaller discharge bags or containers. The smaller platform can be lowered all the way down to the large platform giving room for larger discharge drums without removing the small platform."

Rotor knife in new “super hard” high-grade carbon steel with 20 cutting edges, shaped for precise cutting of uniform pellets from both soft and hard strands. Fixed knife in same super hard tool steel with two cutting edges. Easy and fast adjustment of knife gap."

Control panel integrated in lower body with speed control potentiometer and digital RPM readout."

Swing open thick Polycarbonate door with full view of the cutting operation. Complete double interlocked safety with instant rotor stop when door is opened. Integrated internal protection shield along door front makes it impossible to get in contact with the rotary knife even with minute door opening."

Spring loaded upper Polyurethane rubber roll for smooth and even pulling of the strandsRequest a quote on this line - Click Here!

|

The Blade Flexes over the raised discharge hole area |

Die Face Cutter/Extruder

Our air cooled die face cutter is especially suitable for pelletizing of resins that cannot easily be cut on conventional strand pelletizers, like soft PVC and thermoplastic rubbers. The pellets are cut directly on the die as shown below and the cooling of the cut pellets is by high speed air. A cyclone is connected to the outlet pipe from the pelletizer and this will efficiently separate the pellets from the air flow.

The model shown here is made for our 20 or 25 mm single screw extruders but also larger units can be supplied to fit to all our other single and twin screw extruders

Request a quote on this line - Click Here

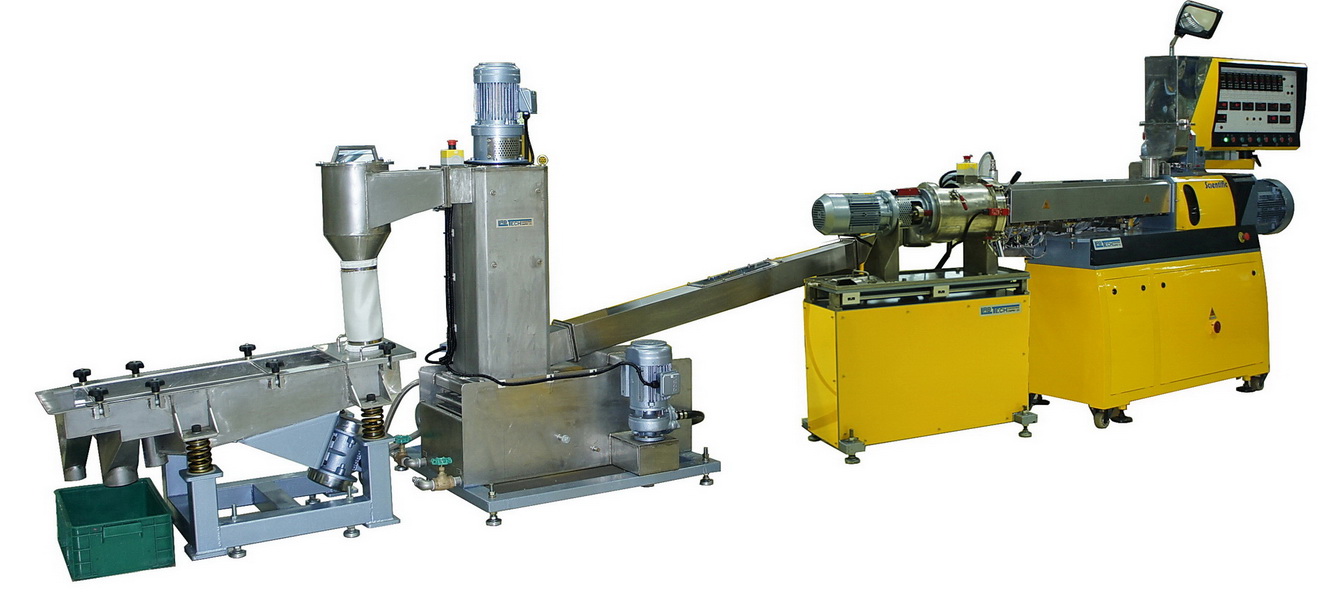

Water Ring pelletizing unit with downstream centrifugal dewatering unit and classifier (can be mated with any of our single screw or twin screw extruders)

A) Water Ring Pelletizer

1. Capacity: up to max 80 kg/ hr based on density 1.0

2. Rotary knife Motor: AC 0.75KW Variable speed

3. Cutter: 1 to 4 knives

4. Knife rotor RPM: 2700 RPM

5. Output hole: 6 holes with diameter 2.8 mm

6. Heater: 1.5 KW

7. Center height: 1100 mm

B) Centrifugal Dewatering Unit

1. Capacity: 80 kg/hr

2. Motor: AC 0.75KW

3. Water Pump: 0.75KW (including heat exchanger)

4. RPM: 1750 RPM

C) Classifier (Only 1 meter long)

1. Vibration Motor: 0.2 KW

2. Classified mesh (Rough): diameters of holes 6 mm

3. Classified mesh (Fine): diameters of holes 2 mm

(6) 25mm pelletizing lines for short run custom master batch production

Call (810) 519-6122 or (810) 516-1700 or (810) 516-1700 for Pricing

Serving Michigan, Ohio, Ind., Ill., Canada for Labtech Engineering Co. Ltd.

14042 Iroquois Woods Dr.

Fenton, Michigan 48430